Manufacturing is a vital component of modern economy as it transforms raw materials into ready-to-use goods through different processes such as 3D printing, casting, structural foam moulding, high pressure injection moulding, and so on, thus providing the products that fuel our society and improving the standard of living for people all across the globe.

The UK has a thriving manufacturing sector, being the 12th biggest manufacturing nation in the world, behind Italy, France, and Taiwan, with a yield estimated at £217bn, according to data provided by Make UK’s latest annual Manufacturing – The Facts survey. Although this ranking reinforces the UK’s standing as a powerhouse in global manufacturing, it doesn’t negate the fact that local companies and enterprises activating in the field have been facing increasing difficulties in recent years.

The UK has been a constant presence in the world’s top ten manufacturing nations for the past decade. It means that the business may be going through some rough times since it fell to 12th place. Last year’s survey by Make UK reveals that eight in ten manufacturers believe that the UK’s lack of industrial strategy puts them at a disadvantage in relation to manufacturing companies from other countries.

Given the current situation, it’s worth digging a little deeper and uncovering the main challenges affecting the manufacturing industry in the UK at the moment.

Skill shortage

The UK’s manufacturing sector is dealing with the same pressing issue that affects many other industries and fields, namely a lack of skilled workers. There is an obvious shortage of specialists in key manufacturing areas such as process optimization, supply chain management, quality control, welding, robotics, electrical engineering and so on, making it difficult for companies to reach their objective and maintain a profitable activity.

As the economy continues to recover after the global health crisis, there is a high demand for qualified manufacturing personnel, but there aren’t enough qualified individuals to fill the available roles. This is not just driving wages up but also puts a strain on current employees, who often have to make up for the lack of staff and work much harder to keep productivity levels high. Pressuring employees into taking on additional tasks and putting in longer hours is not a lucrative or ethical strategy.

At the same time, without the necessary talent, the industry’s development is clearly compromised. Creating educational programs to train the new generations of manufacturing specialists as well as providing better work conditions and incentives for existing employees could provide a solution to this issue.

Digitalisation

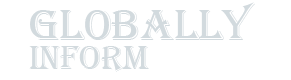

Although digitalisation is an unstoppable trend that’s been taking place for years now, leaving its mark across all areas and aspects of life, many manufacturers in the UK are struggling to keep up with the transformation and embrace emerging technologies such as robotics, the internet of things (IoT), artificial intelligence (AI), augmented reality (AR), virtual reality (VR), and so on.

The benefits brought about by automation and modern technologies are undeniable, as they can streamline operations and lead to increased productivity for companies. For this reason, a large number of manufacturers from different countries are resorting to all kinds of cutting-edge tools and strategies to modernize their production lines. HSV TMP, a Netherlands-based firm that specialises in large plastic injection moulding – which you can learn more about at https://www.hsv-tmp.com/ – offers a good example of how companies can gain a competitive edge through tech implementation.

However, replacing or adapting old processes to integrate with innovative solutions is not a simple undertaking as it involves a thorough understanding of emerging technologies and a comprehensive execution plan that takes into account the need for having the right talent and the right culture to navigate this transformation with ease.

Cyberthreats

Given that digitalisation is taking over the manufacturing industry, and companies are increasingly reliant on tech solutions, producers also have to pay special attention to cybersecurity. Statistics reveal that cyberattacks targeting the UK manufacturing sector rose by a staggering 42% last year, accounting for 20% of all cyberattacks registered during the studied timeframe.

Obviously, firms that have a higher degree of digitalisation are more prone to falling victim to these occurrences, and the consequences can be devastating, ranging from loss of productivity and financial impact to reputational damage, legal liabilities, and even bankruptcy. As a result, manufacturers have to prioritize cybersecurity investments and take all the required measures to make sure their data and assets are thoroughly protected from potential threats.

Rising energy costs

Energy rates in the UK have been on the rise over the past few years, causing difficulties for businesses in all fields and particularly for manufacturing, which is known to be an energy-intensive industry. For some, energy costs have more than doubled in 2022 following Russia’s invasion of Ukraine. While government intervention was beneficial and helped keep things in check for most, it’s hardly a solution to rely on in the long term.

Many companies were forced to increase prices for their products to stay afloat. However, a more sustainable strategy to counter the effects of soaring energy costs is to turn toward renewable energy sources and the use of energy-efficient technologies.

Environmental regulations

In the current context, with the climate crisis becoming a reality that can’t be ignored anymore, having the necessary tools and resources is not enough for manufacturing companies to thrive. UK businesses have to demonstrate their commitment to sustainability through clear actions and comply with much stricter environmental regulations and policies to continue their operations.

While adopting ethical practices and taking steps to reduce environmental impact is a commendable enterprise, it’s certainly not easy for manufacturers to align business objectives and processes with sustainability goals.

All these challenges, although not insuperable, are posting serious issues for UK manufacturers in 2024. It remains to be seen how companies will approach the situation and what solutions they’ll find to push forward in the future.

WDROYO Technology: A Comprehensive Guide 2024

Comments